Dragon seat actuation system

Responsible Engineer – SpaceX

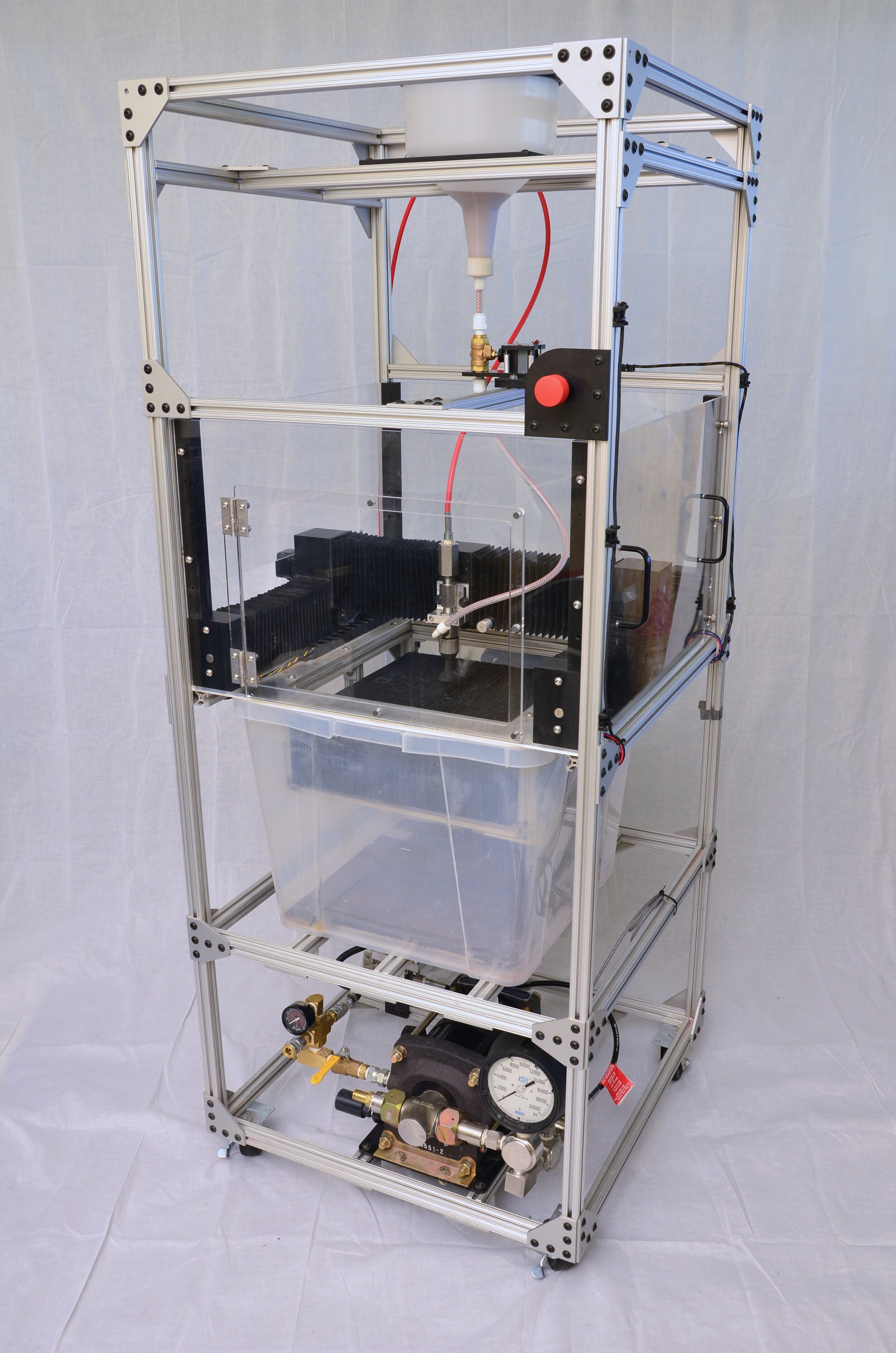

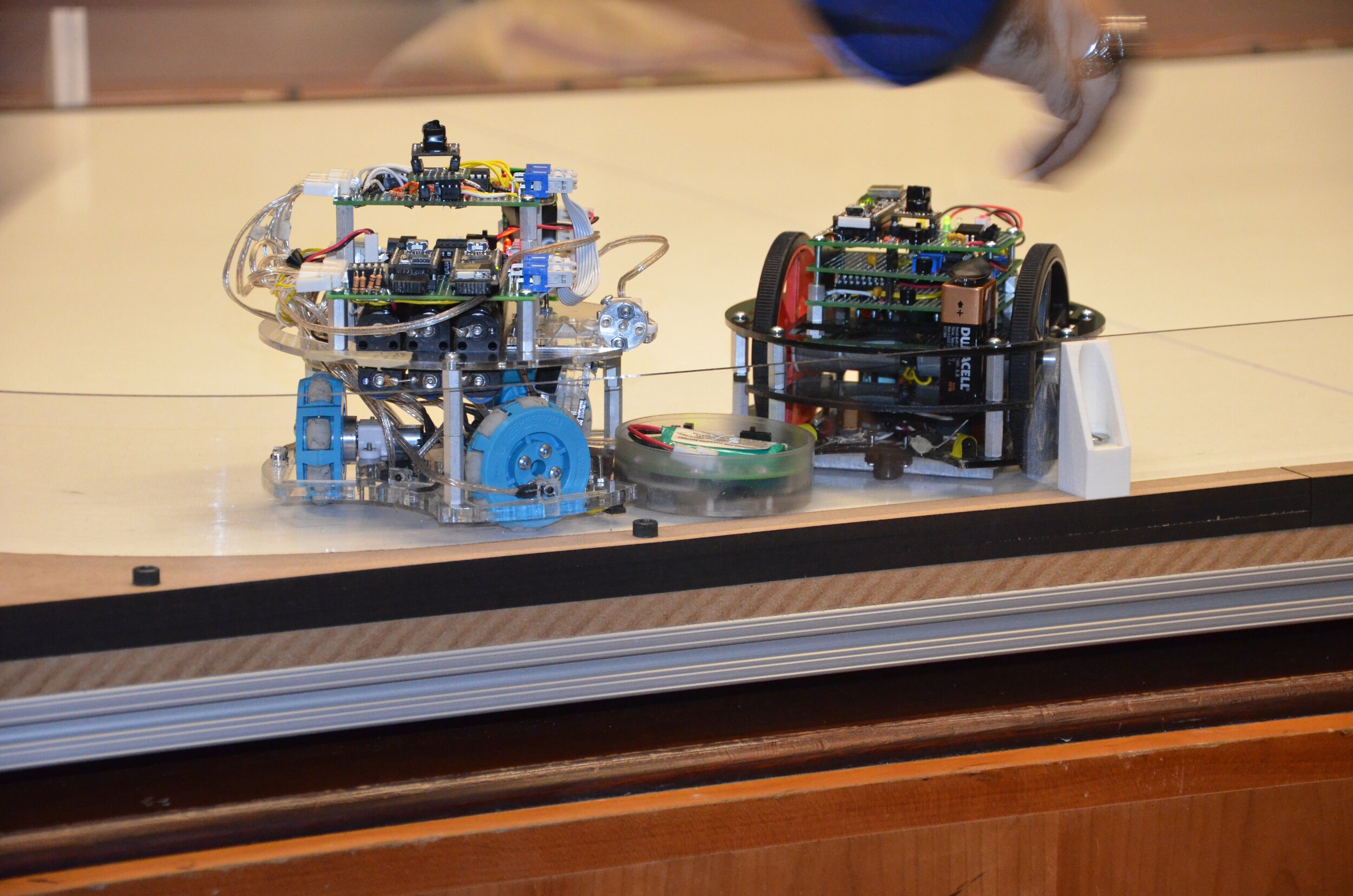

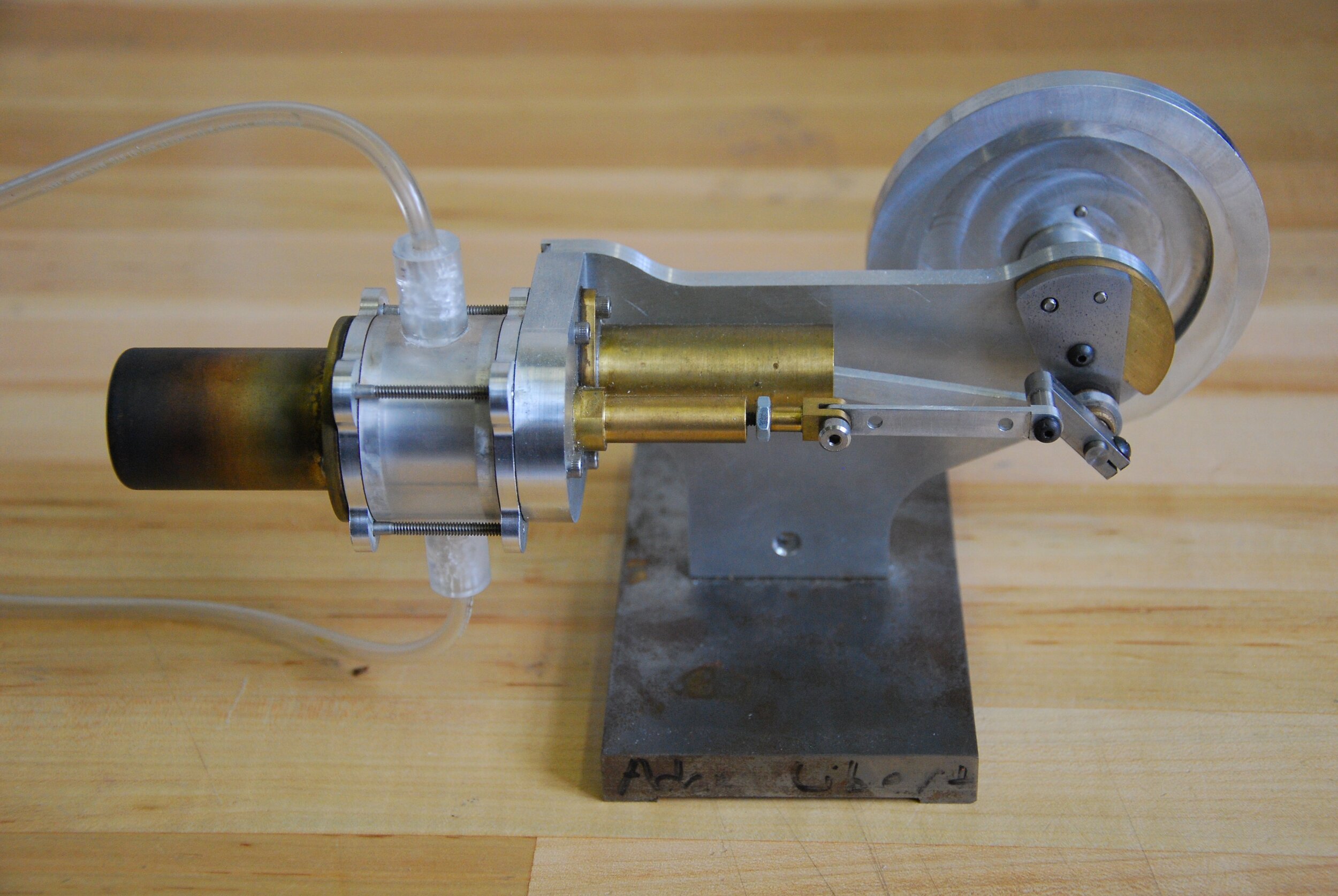

One of the seats in the Crew Dragon capsule interior is shown above. Ensuring that the seat is at the proper angle for any given phase of flight is critical to crew health and safety.

Objective:

Ensure that the Dragon spacecraft’s crew is kept at an appropriate angle with respect to the accelerations they will experience in flight, such that they do not experience any harmful health impacts of the sustained acceleration.

Project Details:

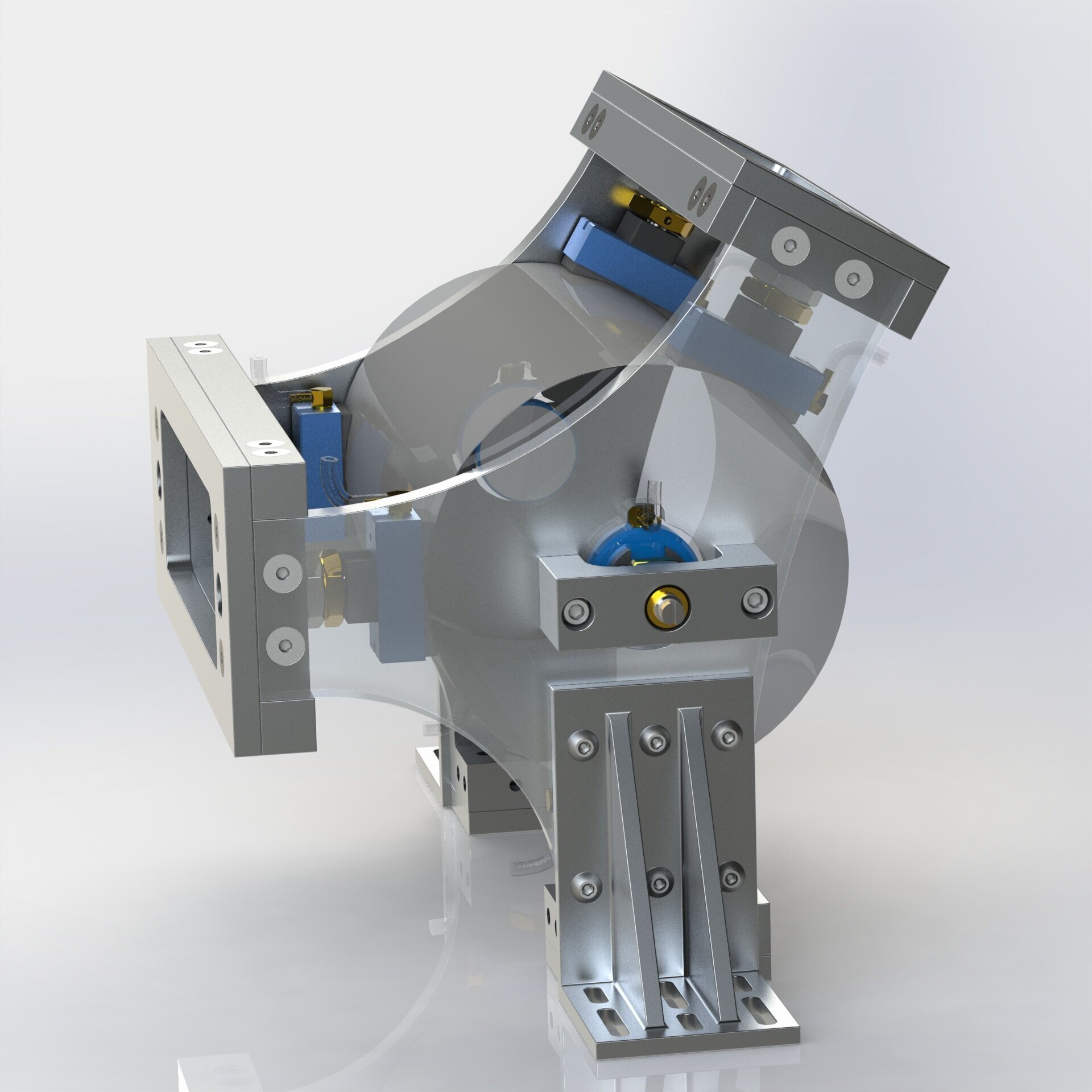

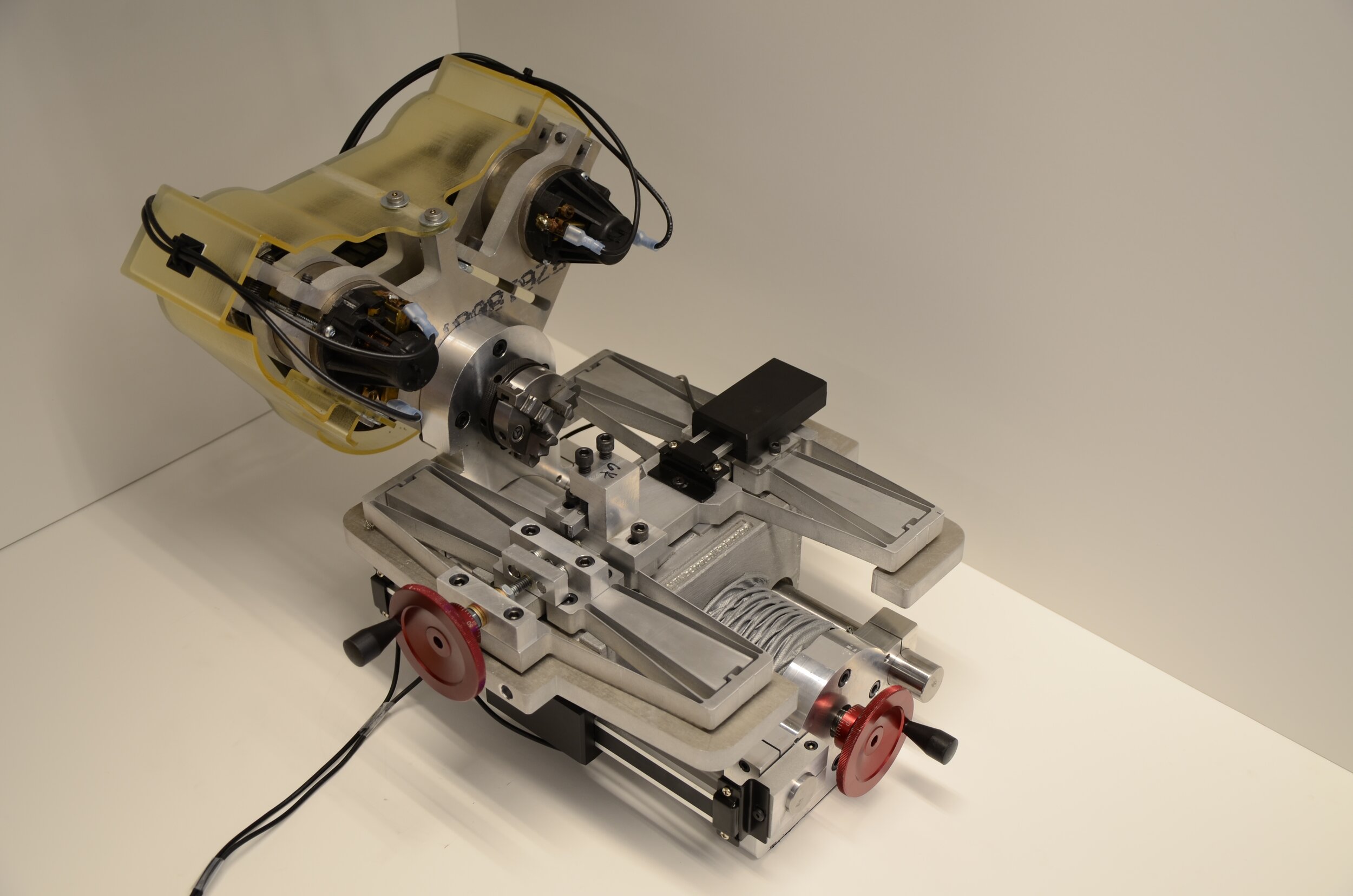

Upon completion of my work on Falcon, I was pulled into the Dragon program by its new Director. He reassigned ownership of the intricate Seat Actuation System to me in order to get it to the finish line. It became clear to me, immediately upon diving into the project, that there were some critical risks to retire. For example, I immediately elected to perform CT Scan of a critical black-box vendor component and proactively identified an internal failure mode that would result in qualification failure. This allowed me to start my redesign effort weeks early and get ahead of the problem. Similarly, through my identification of the project’s critical path, I was able to pull schedule to the left by more

than two months. In parallel, I worked across teams with Human Factors, Flight Software, Avionics Systems, and Space Operations to define the concept of operations (CONOPS) for the system, as well as the Fault Detection, Isolation, and Recovery (FDIR) strategy that had been previously neglected. Throughout this whole process, I worked closely with our NASA customer to ensure that their requirements were met and that the system would be easily certified.

Results

Since I took over the project and pulled in schedule, the Seat Actuation System remained off the critical path of the Dragon program. I have fully defined, developed, and validated both component-level and system-level characteristics to ensure robust operation in flight. In the process, I’ve built up a wealth of knowledge regarding actuation system design and component-level best practices, which I have shared with colleagues through the Motor Mongers group I started to ensure the success of similar programs.

Note: Only publicly released photos and information are presented here.