falcon grid fin actuators

Responsible Engineer – SpaceX

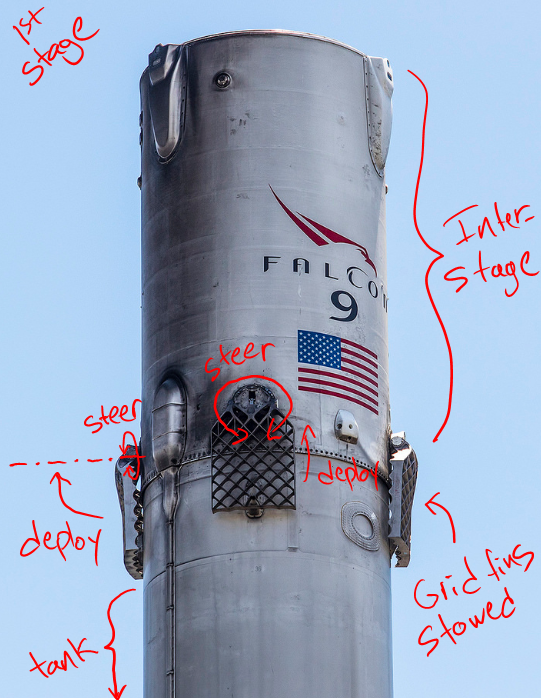

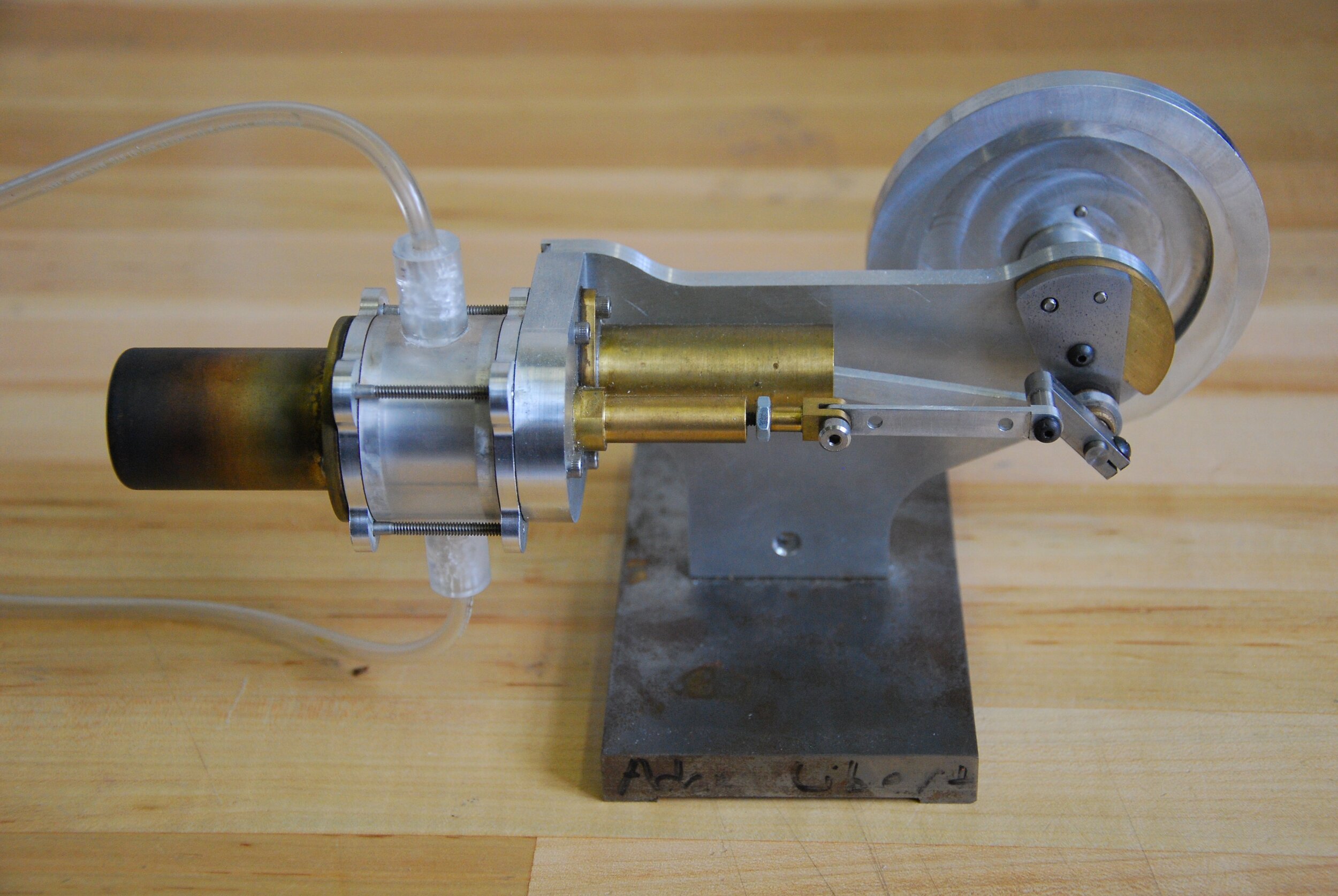

Gwynne Shotwell, the President of SpaceX, looking into the interstage of the Falcon 9 rocket. My four Grid Fin Actuators can be seen circled in red. These actuators connect with the Grid Fin Shafts and are used to steer the rocket’s Grid Fins for landing.

Objective:

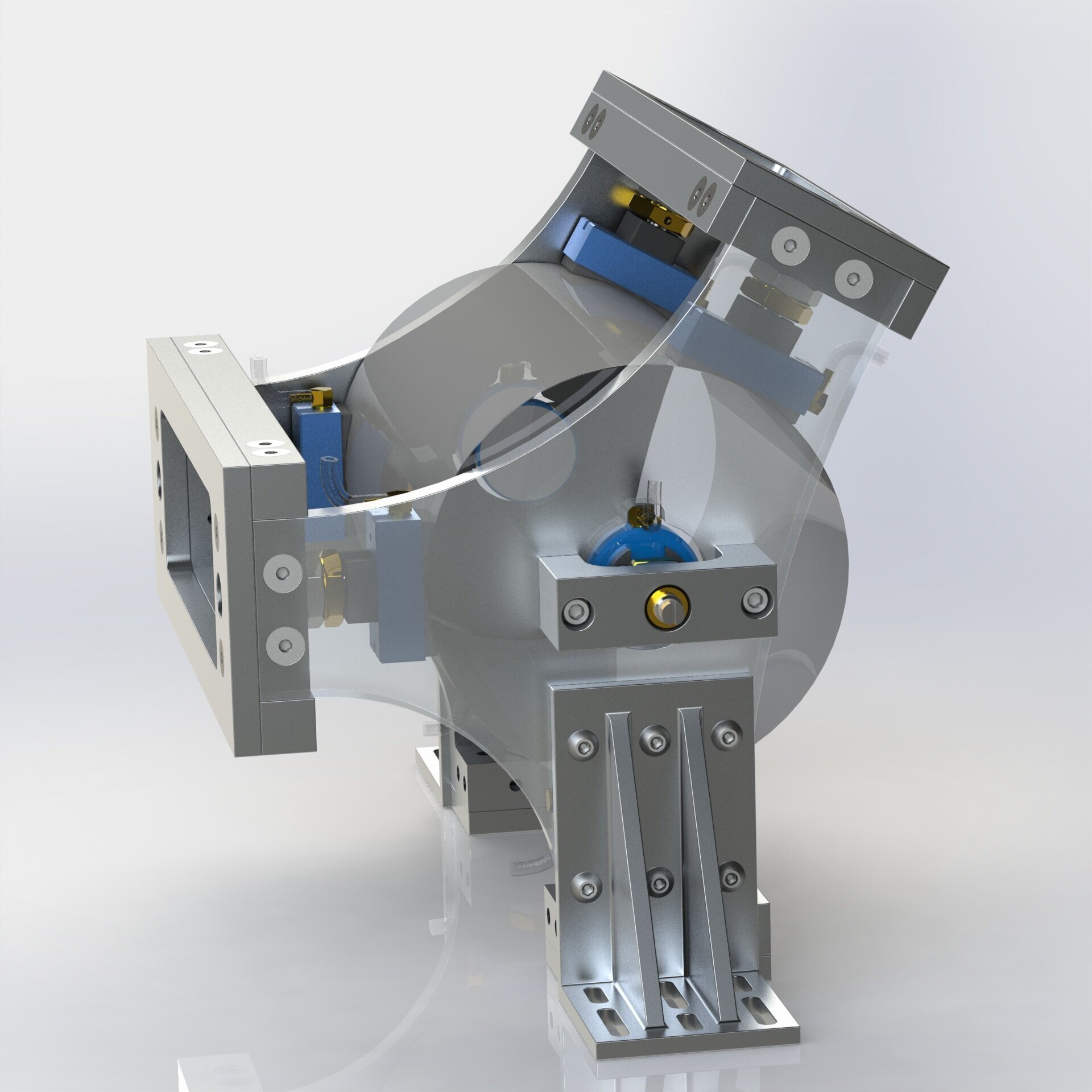

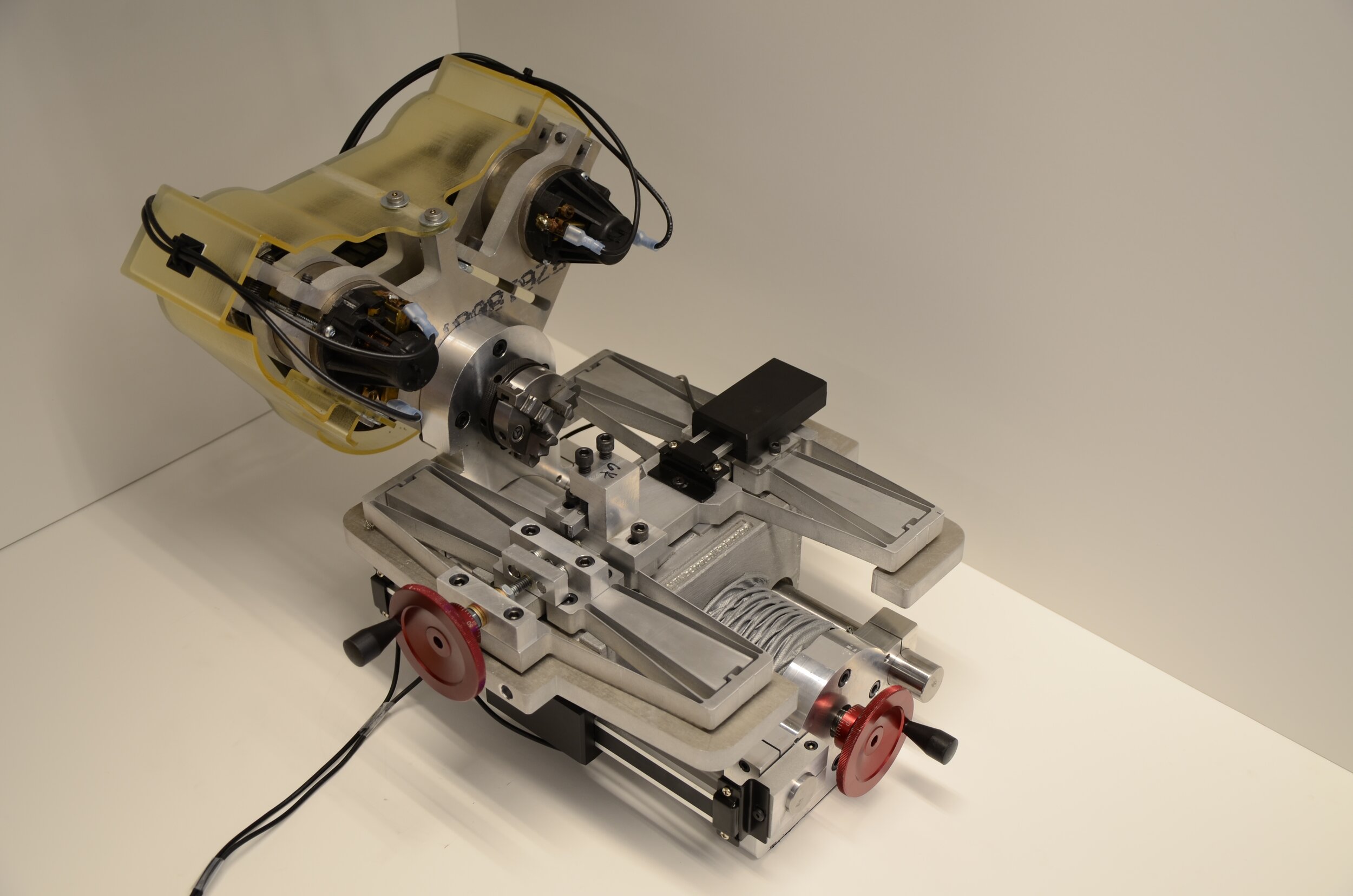

Design the highest-pressure hydraulic actuator ever made at SpaceX, used to control the Grid Fins that enable the Falcon 9 rocket to successfully land and be reused for future flights

Project Details:

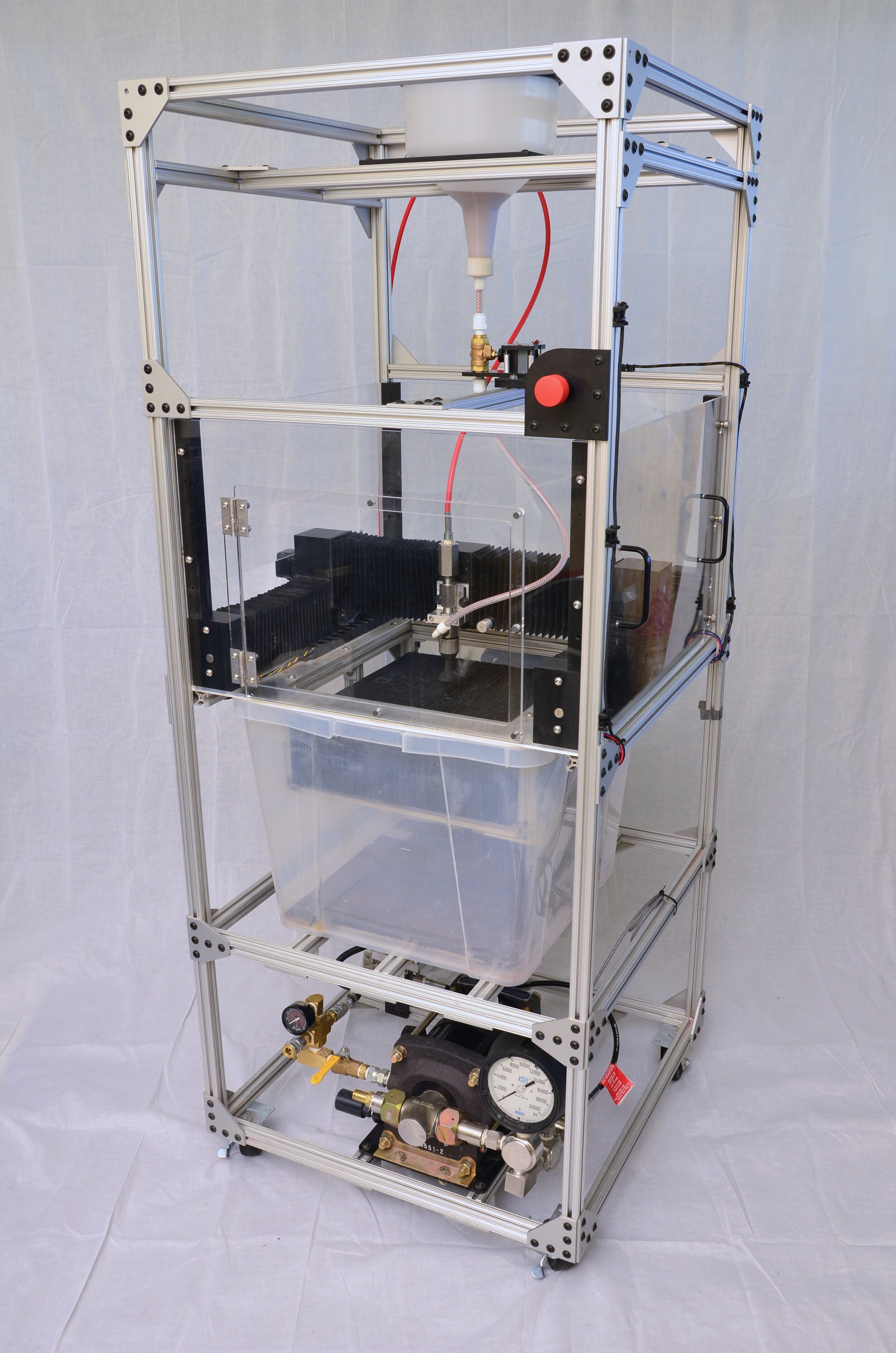

To improve both reuse and reliability, I took on the project of designing a new Grid Fin Actuator to be implemented with a block change of the rocket. First, I worked with the Combined Loads Analysis and the Guidance, Navigation, and Control groups to understand what the load and speed requirements were for the actuator. Then, I worked with the Stage Fluids team to understand how to best integrate with the booster’s hydraulic system. Once I gathered all the inputs, I used a combination of hand calculations, Excel workbooks, Matlab models, CAD, and ANSYS to design the actuator, then worked closely with Production and Test teams to build and qualify it.

Results

I successfully designed, developed, qualified, certified, and proactively built up a safety stock of Grid Fin Actuators all within one year of starting the project, staying well ahead of the demand schedule. The actuator met all requirements and has had a flawless flight track record. Additionally, the actuator saved $40k and 20 lbm per booster. Due to its immense capability, low cost, compact packaging, extreme simplicity, and proven reliability, the actuator has gone on to be used for other vehicle projects, and has served as a model for future actuator design.

Note: Only publicly released photos and information are presented here.